Thanks for the welcome guys!

Here's a couple more, I hope the size is better? Still plenty to do, and motivation has been lacking, so I plan to tack/weld, each panel in place and then Finish them when I have a section complete, at least that way I will see some progress!

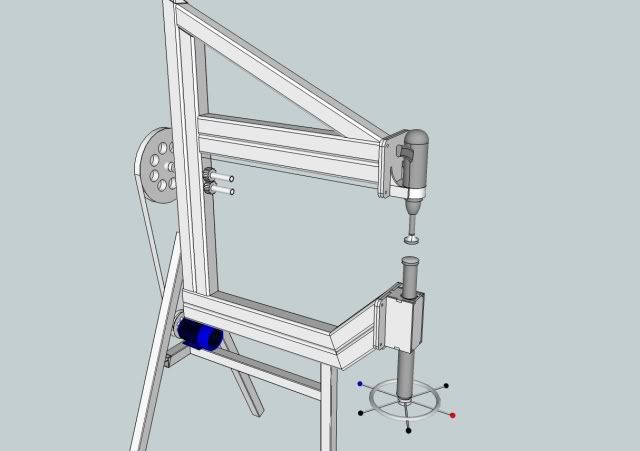

In other news, I have been contemplating making a combo wheeling machine, here is my idea as posted on another forum.

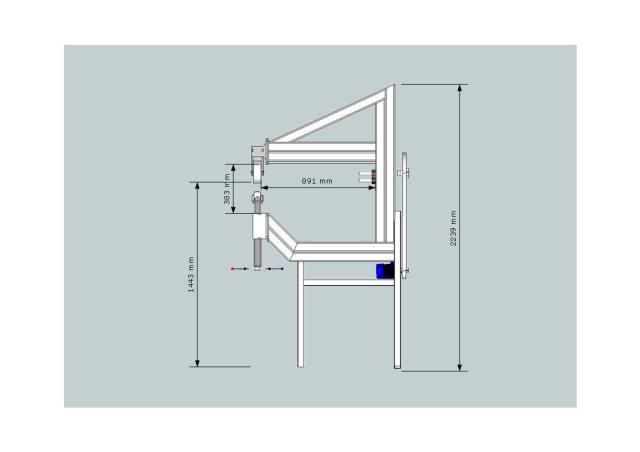

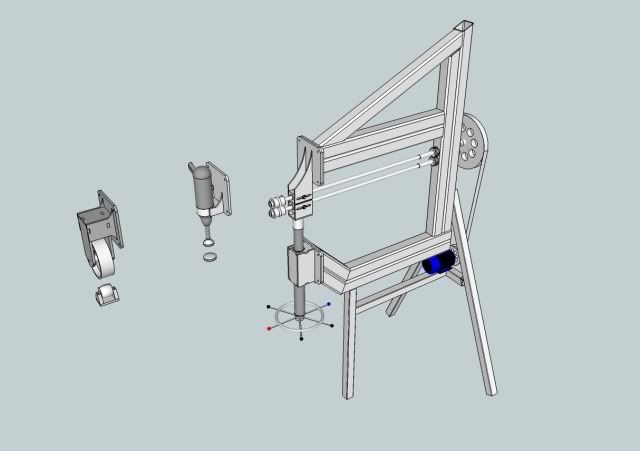

I've been mulling over an idea in my head, now that I have worked out how to use google sketchup, I have my idea on Paper, and am looking for feedback on the design.

I know combination machines are generally a compromise, But my thought is, my funds are limited, all 3 machines are built around the same premise of a strong, rigid C frame, and the design allows for more frames to be built if and when my needs to have more then one machine in use are required.

The machine is my own interpretation of the "low buck" machine, but with design changes to suite my needs and remove several dislikes I have with it, such as the small upper wheel.

The design will use "cheap" components Ie wheel and anvils, but I think there is enough scope in the design, to upgrade the fixtures when the budget allows.

The C frame is constructed from 75X75X5 RHS, with two lengths laminated for extra rigidity.

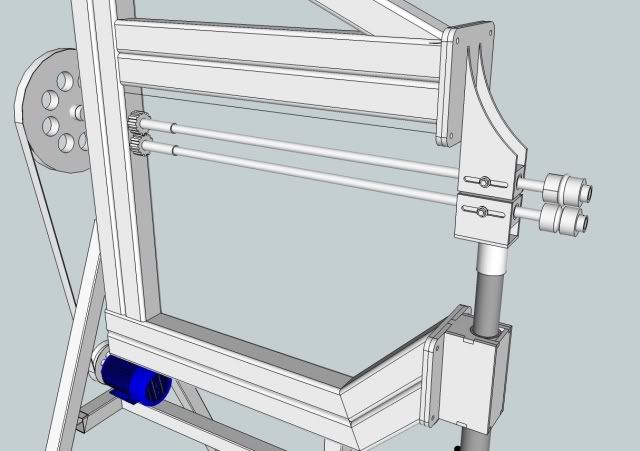

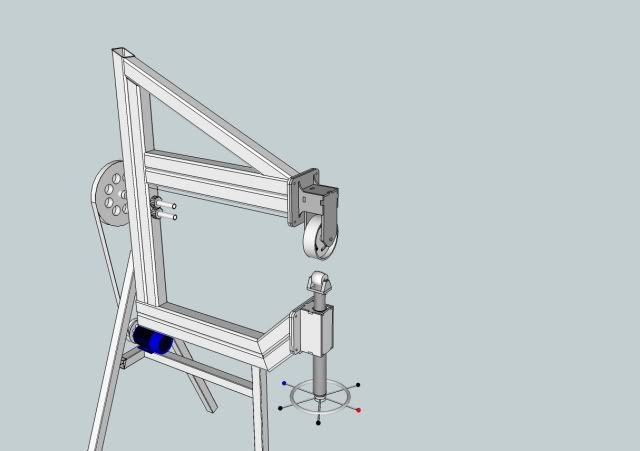

The machine has 2 receiver plates 8mm thick, that will allow the fixtures to be interchanged. The lower adjuster will be designed to receive the lower wheel, the planishing dies and the lower bead roller.

The Beadroller will have two keyed shafts that will slide into the output shafts from the drive gearbox, which will remain permanently attached to the frame. The design allows for both dies to be adjusted for diffent offset and locks with pinch bolts. The bearing blocks will have more clearance, and I am yet to design a gate/guide.

English wheel, I will probably change this design to incorporate a quick release into the upper holder.

Plaishing hammer, may also receive a quick release.

I am design is in its infancy, So I am open to suggestions and of course critique.

The plates for the fixtures and holders will all be laser cut, as I have a friend who can do this for me cheaply. My thought was to modify a trailer jockey wheel for the lower adjuster, I need to check if i can key the inner shaft and use bolts to adjust the slop.

Thoughts?