|

|

|

#1

|

|||

|

|||

|

Hi Everyone,

My name is Jez, I live on the North side of Brisbane. I have always played with cars and bikes, and have been slowly building a business for myself doing custom paint and Airbrush. Slowly as the business evolves I have been doing more resto work. I am completely self taught and am realizing that the only way I can make a name for myself is to do the best I can at every aspect of my trade. This is what led me to the site, I need to learn how to shape metal to the best of my abilty, and there is only so much one can learn, without the guidance of skilled and experienced craftsman. My business is only small, but though perseverance I want to make it successful. I realize success not only comes from experience but also efficiency, my real weak point when it comes to metal shaping. I should probably mention at this point that I am not expecting it to be a 5 minute learning curve, but my goal is to build up my skillset, learning from each job I do, and using less filler each and every time. My current project is a Ford XY Falcon ute. I had quoted on this job initially as a colour change respray. After the customer had it blasted the true state of the vehicle changed the game! Here are a few shots of the state of it showing the "quality" of previous repairs. What drove in for the original quote  Torque box, the patch is 0.6mm on a plate that is 3mm!  Rad support "repair"  Firewall Patch  Plenum Repair  And now some of the repairs, these haven't been "finished" yet Bumper mounts  New torque boxes   Side of firewall  Firewall Patch Start, would have loved to press this, but not possible with my equipment or time frame   And a few quick pics of my previous work           As you can see, I take a lot of pride in my work, I hope that I can gain knowledge from the Vast array or experience here, and hope I can also contribute in some way. Cheers, Jez |

|

#2

|

||||

|

||||

|

Hi Jex, Wow, you certainly have no where to go but up on those previous repairs.

I like the Mustang. Btw, your photos are a bit on the large size. 600-800DPI makes for good internet viewing.

__________________

Kerry Pinkerton |

|

#3

|

||||

|

||||

|

Jez, Thanks for the very nice introduction and pictures of your projects. Welcome to the site, hope you find it helpful. Looks like you are well on your way to being a good metal shaper. Thanks for joining us here.

__________________

Joe Hartson There is more than one way to go to town and they are all correct. |

|

#4

|

||||

|

||||

|

Welcome Jez,

Those are some really nice pics, I especially liked the view along the rear quarter of the Mustang. I could be a little biased though, one of my first cars was a 68 Fastback! I liked your solution to the firewall problem too, that's a pretty slick way of dealing with that. Thanks for joining us Jez, keep us posted on what you're up to.  Ken

__________________

Ken Has anybody seen that key I left in the chuck? See Ken's Metalshaping Gallery at: http://home.cogeco.ca/~kenb2/index.html Website updated June 2011 |

|

#5

|

|||

|

|||

|

Thanks for the welcome guys!

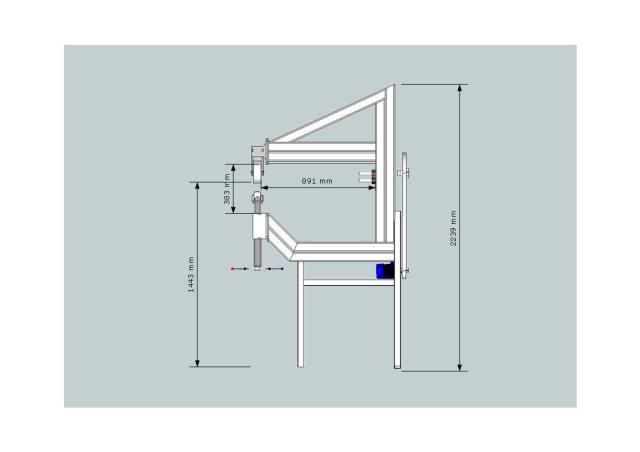

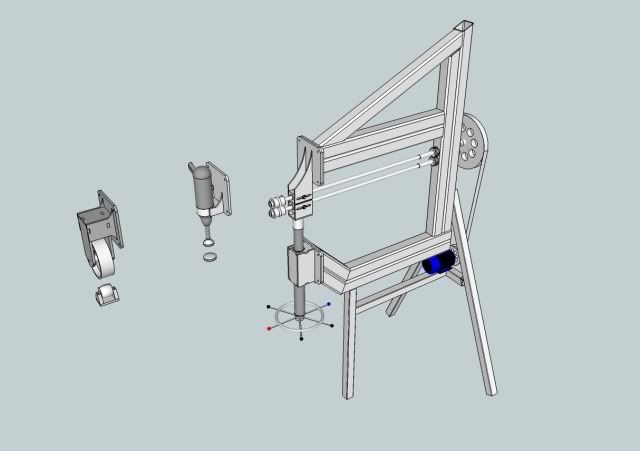

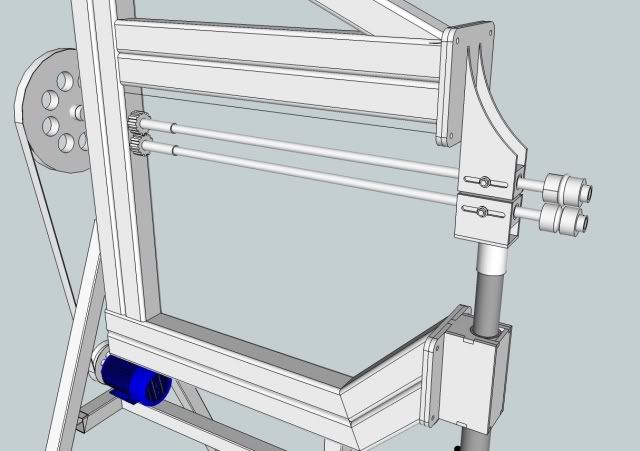

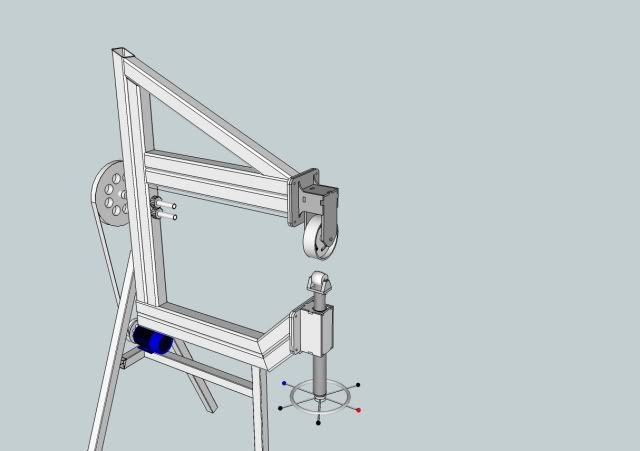

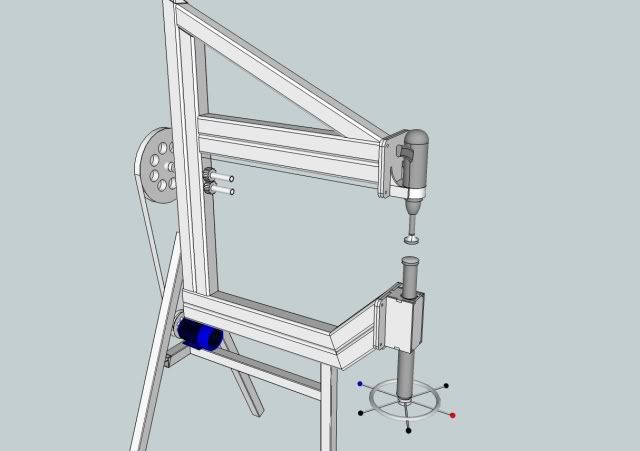

Here's a couple more, I hope the size is better? Still plenty to do, and motivation has been lacking, so I plan to tack/weld, each panel in place and then Finish them when I have a section complete, at least that way I will see some progress!     In other news, I have been contemplating making a combo wheeling machine, here is my idea as posted on another forum. I've been mulling over an idea in my head, now that I have worked out how to use google sketchup, I have my idea on Paper, and am looking for feedback on the design. I know combination machines are generally a compromise, But my thought is, my funds are limited, all 3 machines are built around the same premise of a strong, rigid C frame, and the design allows for more frames to be built if and when my needs to have more then one machine in use are required. The machine is my own interpretation of the "low buck" machine, but with design changes to suite my needs and remove several dislikes I have with it, such as the small upper wheel. The design will use "cheap" components Ie wheel and anvils, but I think there is enough scope in the design, to upgrade the fixtures when the budget allows.  The C frame is constructed from 75X75X5 RHS, with two lengths laminated for extra rigidity.  The machine has 2 receiver plates 8mm thick, that will allow the fixtures to be interchanged. The lower adjuster will be designed to receive the lower wheel, the planishing dies and the lower bead roller.  The Beadroller will have two keyed shafts that will slide into the output shafts from the drive gearbox, which will remain permanently attached to the frame. The design allows for both dies to be adjusted for diffent offset and locks with pinch bolts. The bearing blocks will have more clearance, and I am yet to design a gate/guide.  English wheel, I will probably change this design to incorporate a quick release into the upper holder.  Plaishing hammer, may also receive a quick release. I am design is in its infancy, So I am open to suggestions and of course critique. The plates for the fixtures and holders will all be laser cut, as I have a friend who can do this for me cheaply. My thought was to modify a trailer jockey wheel for the lower adjuster, I need to check if i can key the inner shaft and use bolts to adjust the slop. Thoughts? |

|

#6

|

||||

|

||||

|

Jex, please put your name in the signature part of the userCP.

As far as the frame goes, it's a really weak design in twist and not that good in vertical strength either. If you want a multipurpose frame that's one thing but I'd suggest building a really stiff frame, deflection AND twist.

__________________

Kerry Pinkerton |

|

#7

|

||||

|

||||

|

Welcome Jex!

looks like you have your work cut out for you  try to fix that mess

__________________

Rick Scott The second mouse gets the cheese! |

|

#8

|

|||

|

|||

|

Thanks guys, the whole job is far bigger then I anticipated, and of course is no longer profitable, but at least is sharpening my skills.

Kerry, Thankyou for your input, I will redesign the frame and post up when I get a chance.

__________________

Jez - Karnage Kustoms |

|

#9

|

||||

|

||||

|

Hi Jez, welcome to the site. The first time I read this I thought those pics were of the work YOU did and I thought "Damn, a welding class would be the first order of business!"

I read it again and realized that you were fixing what had already been "fixed" Looks like you do some nice paint work man. The Mustang looks great. Thanks for showing us.

__________________

Grant |

|

#10

|

|||

|

|||

|

Welcome to the site, I think the guy who did the original welding on your car must travel the world welding up cars 'cos that welding looks really familiar. You have done some nice work there. My observation about your machine design is that changing the tools on the frame between planisher, wheel and 'beader' would get old very quickly.

David

__________________

Metalshaping DVD. www.metalshapingzone.com Metalshaping with hand tools on youtube http://www.youtube.com/watch?v=IGElSHzm0q8 All things are possible. |

|

|

|